|

||||||||

|

SeEpMa Automation GmbH die ehemalige Firma BS Müller GmbH Spezialmaschinen Wilhelm-Röntgen-Str.30 D-63477 Maintal Germany |

||||||||

|

||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

__________________________________________________________________________________ |

|

|||||||

|

|||||||

|

|||||||

|

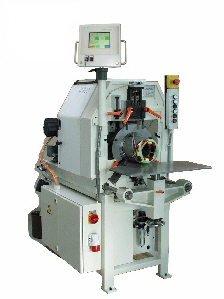

Lacing machine SM1 The lacing machine SM1 works on the principle of the rotating lacing head and stationary stator. Cable exits of the stators can be securely fixed in a mounting ring. A clear display allows a stitch- and speed programming. The machine is indexed by a servo motor and a Siemens S7 PLC. The machine works with in many applications tested BS Müller lacing head NK01. The lacing head has a curved, closed needle (no hook needle). The robust construction and the principle of parallel cord lacing of the winding head allows a very tightly bandage when needed, but it can also be adjusted a loose lacing. The operator is protected from injury by a complete encapsulation of the lacing head and its lacing elements. At the lacing head a pressure shell for fixing the winding head, the phase insulation and the wires can be mounted. On a horizontal operating table, the stators can easily and without much effort pushed into the stator fixing tool. Set-up times are approximately 4-8min. The stack length does not require any modification of the machine. max. Stator OD 260mm (larger on request)

|

|||||||